Properties affecting the functionality and aesthetics of windows made in the MB-86 system:

The profiles of the system have a three-chamber structure. The structural depth of window profiles is: 70 mm (frame), 79 mm (sash), and doors – 70 mm and 70 mm, respectively. Such accepted depths of sash and frame profiles give the effect of one plane from the outside when closed – in the case of windows, and the effect of facing surfaces of the sash and frame – in the case of doors. The shape of the profiles ensures slender and strong window and door structures.

The MB-70 system is characterized by a sensationally low value of the heat transfer coefficient U due to the use of special thermal barriers and seals. This is of great importance in the era of increasing requirements in the field of energy management and environmental protection. The Uf factor for the structure of the MB-70 system, depending on the used profiles and accessories, is from 1.5 to 2.39 W/(m2K). The system uses profiled omega-shaped thermal insulation with a width of 34 (windows) and 24 (doors) mm, made of polyamide reinforced with glass fiber. The proposed shape of the spacers increases the rigidity of the profiles compared to flat spacers and facilitates the drainage of the profiles, thus ensuring proper thermal insulation in all weather conditions. Thermal gaskets used in windows additionally have a seal at the junction of the profile and gaskets, as well as protrusions that divide the chamber between the inner and outer aluminum profiles into three parts. Hermeticity is ensured by the use of special gaskets made of two-component EPDM synthetic rubber: solid and cellular, which guarantees resistance to aging over many years of operation and very good thermal insulation. MB-70 is the first system in which this type of material was used for the manufacture of the central seal.

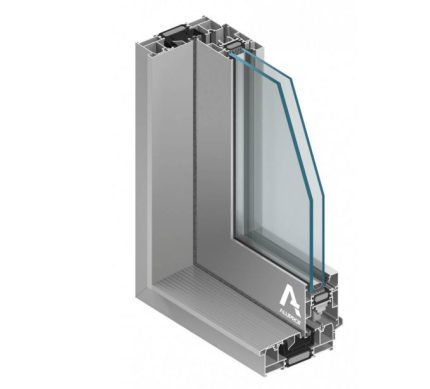

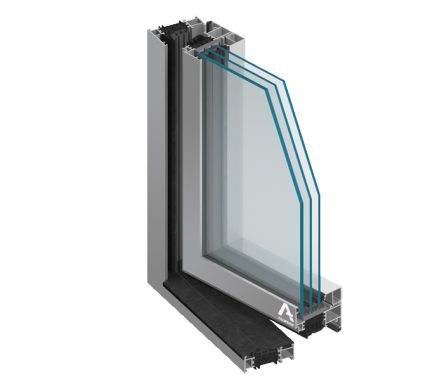

The system allows the use of double-glazed windows with a thickness from 21 mm to 57 mm in window sashes and from 12 mm to 48 mm in fixed windows and door leafs. Such a wide range of filling thickness guarantees the possibility of using all standard and non-standard glass units.

A large selection of colors in the standard palette allows us to satisfy the needs of the most demanding customers. Color coatings are made by powder coating or anodizing.

The MB-70 system is the basis for solutions with increased thermal insulation: MB-70 HI, MB-70US HI and a cold and warm facade based on MB-70CW HI windows.

This system also allows building anti-burglary windows and doors in classes RC1 – RC3 and windows MB-70RC4 with the highest resistance to theft in class RC4

Reviews

There are no reviews yet.