WE MANUFACTURE

ARKA COMPANY

Has been working in the window market since 1998. High professionalism, responsibility, directness and flexibility in relations, constant development, creative potential and full dedication to their work allowed the company to take a strong position in the window market of Ukraine.

“ARKA” is a promising company that is dynamically developing, modern production, the latest materials and technologies, high quality products, competent employees.

The main area of activity is the production of translucent metal-plastic structures from REHAU PVC profile and aluminum profiles, providing a full package of services for comfortably solving glazing problems.

OUR ADVANTAGES

PROFILE SYSTEMS

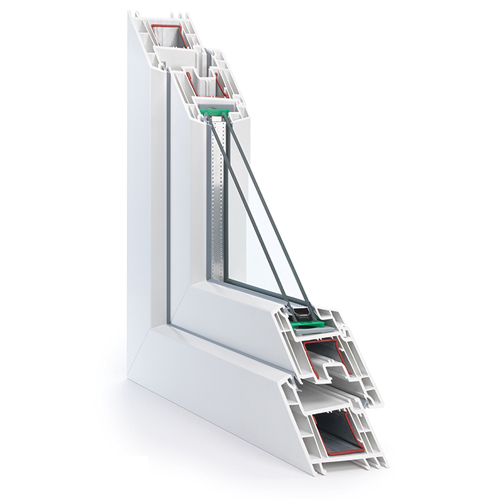

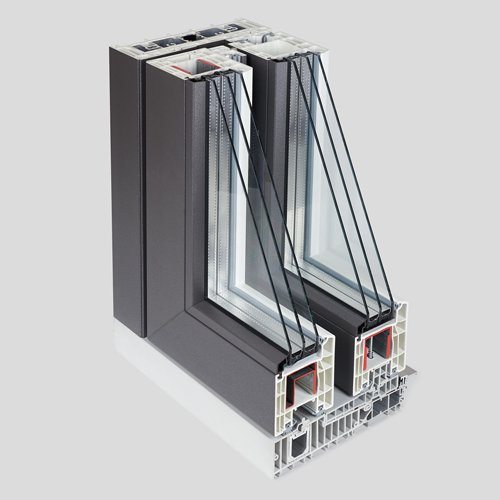

Windows from the REHAU Euro-Design 70 profile system

will ensure the optimal level of thermal insulation of your home and help reduce heat loss in the room, and therefore save money on heating and air conditioning.

- Construction depth: 70 mm

- Number of cameras: 5 cameras

- The maximum thickness of the glass unit: up to 41 mm

- Profile package height (frame + sash): 116 mm

- Heat transfer coefficient – Uf: 1.6 W/m²K

- Heat transfer resistance coefficient** – Rf: 0,77-0,80 m²K/W

- Sound insulation – Rw,P: 43 dB

- Burglary: up to class 2 (ENV 1627)

- Air permeability: class 4 according to EN 12207

- Water resistance: up to class 9A according to EN 12208

- Porch sealing: EPDM / 2 circuits

REHAU Brillant-Design

provides coziness and comfort, even when there is snow and blizzard outside. Thanks to the box depth of 70/80 mm and two sealing contours, windows made of the REHAU Brillant-Design profile reliably protect against cold, drafts, moisture and dust.

- Construction depth: 70-80 мм / 5-6 камер

- The thickness of the double-glazed window: up to 41 mm

- Sealing: 2 EPDM circuits

- Profile heat transfer coefficient* / heat transfer resistance coefficient: = Uf*= 1.3-1.2 m²K/W / Rf**= 0.77-0.82 W/m²K

- Sound insulation*: – Uf = 1.6 W/m²K

- Heat transfer resistance coefficient**: Rf = 0.77-0.80 m²K/W

- Sound insulation: up to Rw,P 43 dB

- Burglary: up to class 2 (ENV 1627)

- Air permeability: class 4 according to EN 12207

- Water resistance: up to class 9A according to EN 12208

REHAU SYNEGO SLIDE

these are parallel-sliding windows and doors with AST-type opening and hermetic sealing along the perimeter of the vestibule.

- Opening scheme: A

- Coefficient of thermal conductivity: Uf 1.3 W/m²K

- Depth along the frame: 156 mm

- Depth along the sash: 80 mm

- Maximum construction dimensions: 4000 mm x 2600 mm

- The maximum dimensions of the sash: 2000×2500 mm

- The maximum weight of the sash: 200 kg

- The thickness of the double-glazed window: up to 51 mm

- Water permeability*: 9 A

- Breathability*: Class 4

- Burglary*: RC2

HST SYNEGO lifting and sliding systems

They belong to the portal-type systems designed for arranging large-sized doorways (width up to 10 m, height up to 2.8 m).

- Type of profile system: SYNEGO

- Type of opening: Lifting-sliding door

- Profile material: RAU-PVC

- Gasket material: RAU-SR, RAU-PREN (black, gray)

- Box/door depth: 190mm/80mm

- Number of cameras: 5 cameras

- Maximum filling thickness: up to 51 mm

- Box profile height: 63 mm

- Sash profile height: 101mm/ 40mm (panoramic sash)

- Maximum sash weight: 400 kg

- The maximum size of the sliding leaf: 300 cm x 260 cm (H x H)

- Heat transfer coefficient Uf: up to 1.3 W/m²K *

- Heat transfer resistance coefficient Rf: 0.77 W/m²K **

- Resistance to wind loads: up to class B3 according to DIN EN 12210

- Water permeability: up to class 9A according to DIN EN 12208

- Air permeability: class 4 according to DIN EN 12207

- Durability: class 2 according to DIN EN 12400

- Burglary: up to RC2 according to DIN EN 1627

- Decorative design: lamination and varnishing according to the RAL color palette

- Opening schemes: A (2 parts, 2 asymmetric parts, 3 parts), C, G1 (G-A 3 parts), K (3 parts, 4 parts)

HST GENEO lifting and sliding systems

They belong to the portal-type systems designed for arranging large-sized doorways (width up to 10 m, height up to 2.8 m).

- Type of profile system: GENEO

- Type of opening: Lifting-sliding door

- Profile material: RAU-PVC

- Gasket material: RAU-SR, RAU-PREN (black, gray)

- Box/door depth: 190mm/80mm

- Number of cameras: 5 cameras

- Maximum filling thickness: up to 53 mm

- Box profile height: 63 mm/97 mm

- Sash profile height: 101mm/ 40mm (panoramic sash)

- Maximum sash weight: 400 kg

- The maximum size of the sliding leaf: 300 cm x 270 cm (H x H)

- Heat transfer coefficient Uf: up to 1.3 W/m²K *

- Heat transfer resistance coefficient Rf: 0.77 W/m²K **

- Resistance to wind loads: up to class B3 according to DIN EN 12210

- Water permeability: up to class 9A according to DIN EN 12208

- Air permeability: class 4 according to DIN EN 12207

- Durability: class 2 according to DIN EN 12400

- Burglary: up to RC2 according to DIN EN 1627

- Decorative design: lamination and varnishing according to the RAL color palette

- Opening schemes: A (2 parts, 2 asymmetric parts, 3 parts), C, G1 (G-A 3 parts), K (3 parts, 4 parts)

REHAU Euro-Design Slide and REHAU High-Design Slide sliding systems

They are used for glazing window and door openings of balconies, loggias, terraces and other unheated rooms.

Technical indicators of REHAU Euro-Design Slide:

- Opening function: sliding door

- Material: sliding PVC

- Structural depth of the frame / sash: 60 mm / 41 mm

- Number of frames/sash cameras: 3/2

- Filling thickness: 4 – 24 mm

- Maximum construction width: up to 4 m

- Sash width: 300 – 1400 mm

- Sash height: up to 2400 mm

- Sash weight: up to 100 kg

- Number of sashes in the structure: 2, 3, 4, 6

REHAU Euro-Design Slide and REHAU High-Design Slide sliding systems

They are used for glazing window and door openings of balconies, loggias, terraces and other unheated rooms.

Technical indicators of REHAU High-Design Slide:

- Opening function: sliding door

- Material: sliding PVC

- Structural depth of the frame / sash: 86 мм / 60 мм

- Number of frames/sash cameras: 3/2

- Filling thickness: 4 – 33 мм

- Maximum construction width: до 4 м

- Sash width: 550 – 2000 мм

- Sash height: до 2700 мм

- Sash weight: до 180 кг

- Number of sashes in the structure: 2, 4, 6

CALL A MEASURER

and we will answer your questions

HOW WE WORK

SUBMIT AN APPLICATION

Windows made of aluminum and PVC profiles from the manufacturer

“Arka” plant has been producing windows made of aluminum profile and PVC profile for more than 20 years. For this, we use only original materials from leading manufacturers. Also, our company is a certified partner of the German concern REHAU, from which we purchase components directly. For the manufacture of aluminum facades and the production of metal-plastic structures, we use modern German equipment and strictly control the quality of products at every stage. Our plant for the production of PVC windows carefully adheres to all standards and manufacturing technologies and regularly trains craftsmen in the “Rehau” training centers.

…

Unlimited possibilities for arranging window and door openings

Our factory not only produces window systems, but also professionally installs them. Our own production of plastic windows allows us to manufacture standard and exclusive designs for:

- balcony glazing;

- decoration of balconies and loggias on a turnkey basis;

- facade glazing of enterprises and shopping centers;

- arrangement of winter gardens;

- decoration of large holes or holes with a complex geometric shape.

The production of plastic windows and doors at the “Arka” company’s factory has truly limitless possibilities for arranging window and door openings.

Rehau window production stages

The production of Rehau windows includes the following stages:

- Cutting of frames and imposts taking into account the standard size of the double-glazed unit, features of the layout and selected fastening. The operation is performed with milling drainage holes, drilling grooves for fastening and reinforcing plastic with galvanized steel.

- Welding of window system parts. This technological operation is performed on a special welding machine. The edge of PVC constructions is melted so as to obtain an even, neat seam.

- The leveling of the seam protrusions is performed when cleaning the corners. For tightness, the corners are processed inside and outside, grooves are prepared for the sealing material.

- Fixation of the sealant and imposts on the plastic.

- Installation of fittings with an equal inter-loop interval. If necessary, install a pressure profile. The doors are connected to the frame and tested for functionality.

- Fixation of double-glazed windows in the profile, which is performed with the help of staples. They, in turn, rely on intra-valve supports.

Thanks to our own production, we can carefully control each of its stages and guarantee the high quality of metal-plastic windows from the manufacturer “Arka”.

Why choose us?

Metal-plastic windows from the manufacturer “Arka” are:

- durability — service life up to 50 years;

- high quality at an affordable price;

- warranty and post-warranty service;

- original fittings;

- compliance with quality standards, including the fire safety standard;

- the ability to perform glazing of any level of complexity;

- a wide selection of decoration options.

Our customers receive fully ready-to-install windows. They are assembled in workshops with modern equipment, and craftsmen strictly follow the technologies recommended by the manufacturer. Our window systems meet the requirements of the State Standard, are easy to use and have a variety of designs.

How to order aluminum profiles and PVC windows?

To order windows made of aluminum profile or PVC construction, you need to take a few simple steps:

- Contact our managers and get detailed advice on the range and cost of windows, production terms, warranty conditions and delivery. You will also be able to discuss all your needs and requirements, get advice on choosing the optimal solution.

- Choose the options and characteristics that suit you — options for double-glazed windows, fittings, profiles and other details.

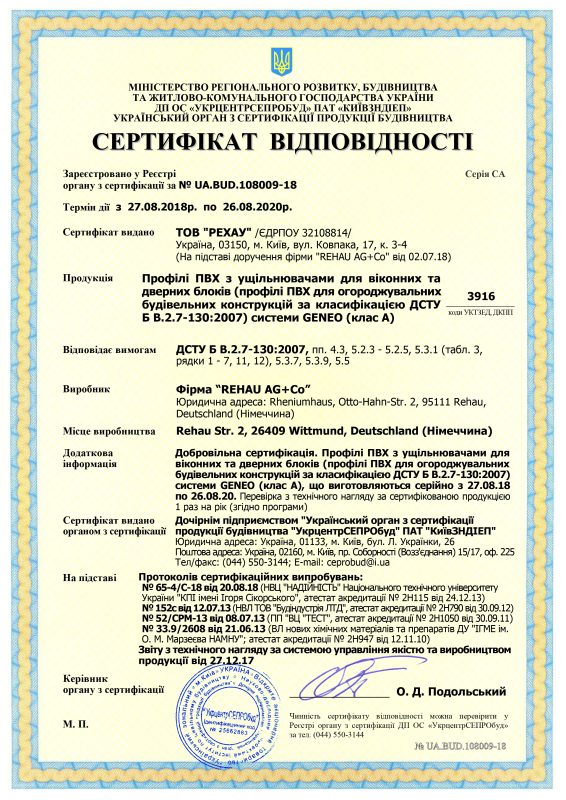

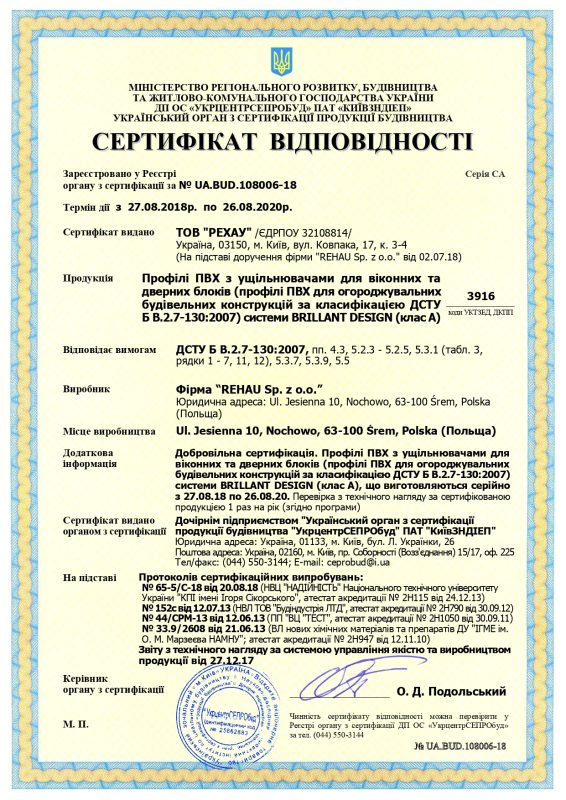

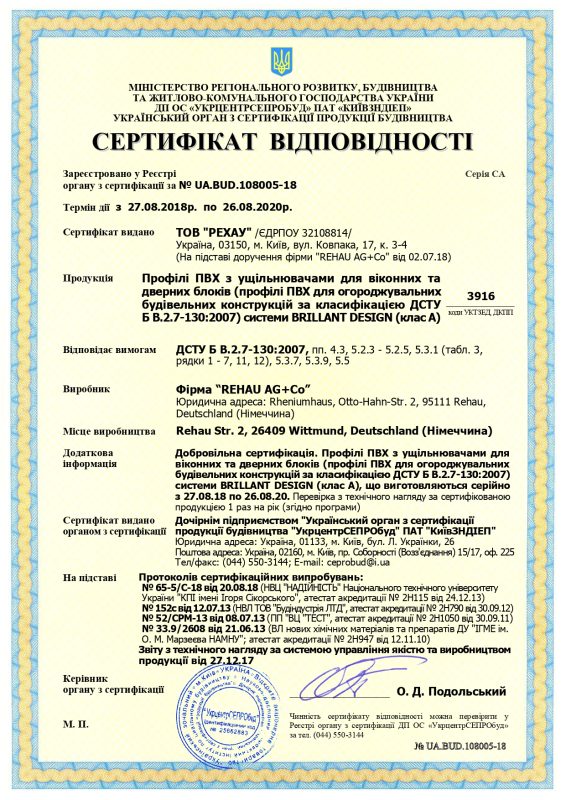

- After you choose windows and additional options, we conclude a written contract with you. This document will specify all the details of the order, including the price, terms of execution, terms of payment and warranty obligations.

- Make payment according to the terms of the contract. After that, we will start making your windows. Plan the delivery and installation of windows on time.

- After installation, check the quality of the doors and windows. Make sure that all terms of the contract are fulfilled. Keep all documents and invoices for the entire warranty period.

As you can see, ordering windows from the “Arka” company is quick, easy and safe. Call us right now and see for yourself.